Pi (polyimide) poda, tsvimbo, sheet, cnc gadzira zvigadzirwa

Muridzi werudzi anozivikanwa nekuumbwa kwemakemikari, kupokana kwemakemikari akanakisa, uye hunhu hweorenji / yeruva. Polyamides yakawedzerwa ne graphite kana girazi fiber kusimbiswa zvine masimba anoshanda kusvika ku 340 mpa Thermoses polymer matrix polyamides inoratidzira yakaderera yakaderera creep uye yakakwirira yakaoma Simba. Izvi zvivakwa zvinochengetwa panguva yekuenderera mberi nekushandisa tembiricha kusvika 232 ° C (450 ° F) uye kwenguva pfupi shanu, yakakwira se 704 ° C (1,299 ° F). [11] Yakaumbwa Polyimide zvikamu uye larevates ine yakanaka kupisa kupesana. Zvakajairika kushandisa tembiricha yezvikamu zvakadai uye laminates kubva kune cryogenic kune izvo zvinopfuura 260 ° C (500 ° F). Polyamides zvakare anodzivirirawo kurwisa murazvo mutserendende uye hauwanzo kufanira kusanganiswa nemurazvo unodzoreredza. Vazhinji vanotakura UL Rating yeVTM-0. Polyimide leminates ane yakasindimara simba hafu yehafu hupenyu pa 249 ° C (480 ° F) kwemaawa 400.

Typical Polyimide zvikamu hazvina kukanganiswa nekuwanzoshandiswa zvinoshandiswa sols uye mafuta - kusanganisira hydrocarbons, esters, geners, esters, batya uye mahwendefa. Ivo zvakare vanorambawo zvisina kusimba acids asi havakurudzirwe kushandiswa munzvimbo dzine alkalis kana inorganic acids. Mamwe mapuranga, akadai seCP1 uye Corin XLS, ari solvent-soluble uye airatidzira yakakwirira optical optical kujekesa. Iyo solubility midziyo inovasiya kune vakananga kurira uye vakaderera tembiricha kurapa mashandisirwo.

Pi Zvinhu

Pi ndiye murazvo wayo unodzoreredza polymer, risingatsvake pakupisa kwakanyanya

Mechanical mechesties yakaderera kunzwa kwekushisa

Izvo zvinyorwa zvine kugona kwakaringana, kunogona kuwana zvinodiwa zvakasiyana-siyana zvekufananidza ruvara

Yakanakisa inobata basa rekutyisa: kupisa kwakanyanya uye kudziya kwakadzika kwekudziya

Kuita Kwemagetsi Kwemagetsi: Yakakwira Electric Insulation

Pi Main application shamba

Inoshandiswa zvakanyanya mumishini, chishandiso, zvikamu zvemotokari, zvemagetsi uye zvemagetsi, zvigadzirwa zvemitambo, mapepa ekuvaraidza, mapepa emafuta, ma pombi yemafuta uye zvimwe zvigadzirwa zveinjiniya uye zvimwe zvigadzirwa zveinjiniya.

Polyimide zvinhu zvakareruka, zvinoshanduka, zvinodzivirira kupisa nemakemikari. Naizvozvo, ivo vanoshandiswa muindasitiri yemagetsi yemabhokisi anochinjika uye sefirimu rekusimbisa pane magnet waya. Semuenzaniso, mune komputa yelaptop, iyo tambo inobatanidza iyo huru yekunyepa bhodhi kusvika pakuratidzira Mienzaniso yeFolyimide mafirimu anosanganisira apical, Kapton, Upilex, vtec pi, norton th uye kaptrex.

Iko kumwe kushandiswa kwePolyimide resin yakafanana neyakawedzera uye passivation layer mune iyo yekugadzira yezvitima zvakabatanidzwa uye mems machipisi. Mazita ekurapa ane hungwaru ane hunyanzvi hwekuwedzera uye ane simba rekusimba, izvo zvinobatsirawo kusungirirwa pakati peiyo polyimide laers kana pakati pePolyimide layer uye yakaiswa simbi yesimbi.

| Munda | Mhosva dzekushandisa |

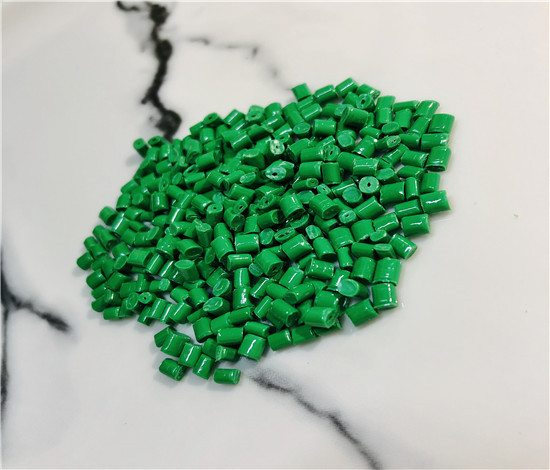

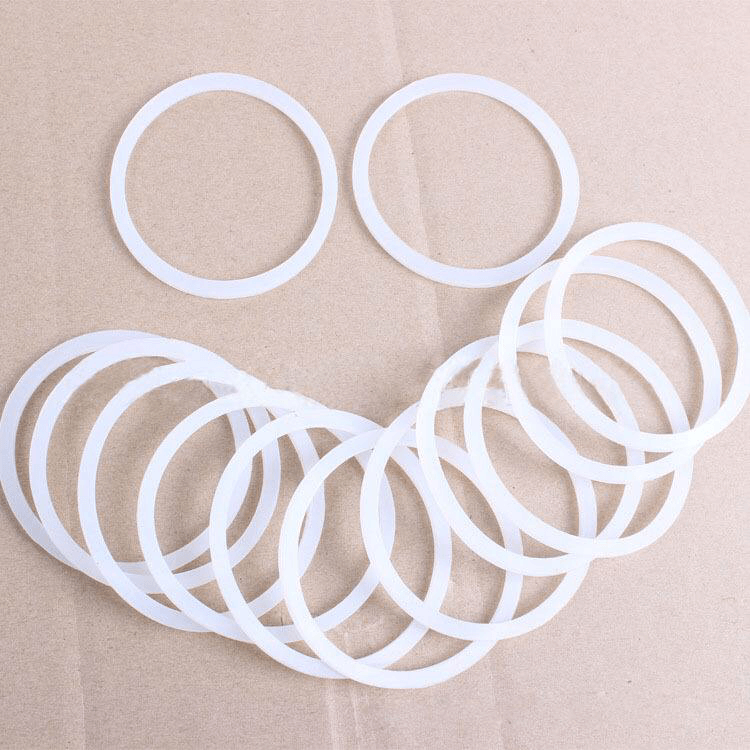

| Indasitiri chikamu | Yakanyanya kupisa yekuzvinyudza-compricating Bearing, compressor piston mhete, seal mhete |

| Zvigadzirwa zvemagetsi | Radiators, kutonhora fan, Door Bless, Fuel Tank Cap, Mhepo Intake Grille, Tangi Yemvura yeTangi, Remamita Holder |

Spla-3D mamakisi uye tsananguro

| Giredhi | Tsananguro |

| SplA-3D101 | Yakakwirira-performance plaim. Maakaunzi maakaunzi kweanopfuura 90%. Kudhinda kwakanaka kuita uye kuwanda. Izvo zvakanakira kugadzikana kuumba, kudhinda kudhinda uye zvakanakisa zvemidziyo. |

| SplA-3DC102 | Pla account ye50-70% uye inonyanya kuzadzwa uye yakadzoserwa. Izvo zvakanakira zvinokonzeresa kugadzira, kudhinda kudhinda uyexcellent mechanical zvivakwa. |