Iyo yekugadzira maitiro ekugadziridzwa epurasitiki emapurasitiki anonyanya kusanganisira: kusanganisa maitiro, kuoneka maitiro, kurongedza.

1. Nhanhatu bvunzo dzekusanganisa: kubhadharisa, kugamuchira, kuchenesa, kupatsanura, kusanganisa, kusanganisa.

2.

3. Kugovana zvinhu: Ita shuwa kuti zvinhu zvakaringana zvisina kukodzera hazvizokanganisa mukuvhiya.

4. Kusanganisa: Kurongeka kweGeneral Kusanganisa ndeye: Chikamu poda, Toner.

Ⅱ. Kudyisa.

Kuburikidza nekudzora komputa, kushaikwa kunodzorwa zvinoenderana nehuremu shanduko.

Zvakanakira:

1. Simbisa chokwadi chezvinhu zvekunyama.

2. Deredza kusekwa kwezvinhu.

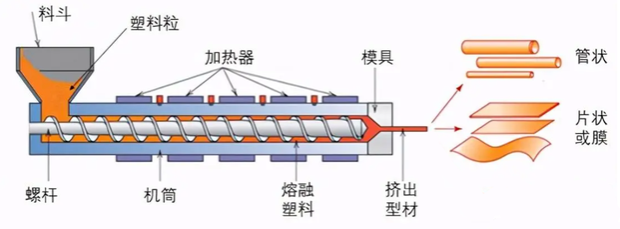

Ⅲ. Screw plasticzing, kubuda, dhirowa.

Ⅲ. Screw plasticzing, kubuda, dhirowa.

Ⅳ. Mvura inotonhorera (kunyura).

Kutonhora uye kutonhora iyo plastiki strip inobuda kubva kune inowedzera.

Ⅴ. Mhepo kuoma (mvura yemvura, banga remhepo).

Bvisa iyo unyoro kubva papurasitiki tambo uye uiise.

Ⅵ. Kubata.

Kazhinji, saizi yemakadhi akacheka ndeye 3mm * 3mm pvc zvinyorwa standard: GB / T8815-2002.

Ⅶ. Sifting (vibrating skrini).

Cheka iyo yakatemwa zvimedu uye kudzora ukuru hwezvikamu.

Ⅷ. Overmagnetization (Magnetic Filter).

Kuyamwa kunze zvimisikidzo zvine tsvina yesimbi.

Ⅸ. Pa-saiti yekuongorora.

Iyo inonyanya kutaridzika kudzora, iyo inoona kuti ruvara rwezvikamu zviri kusvika pachiyero uye kana ichizivikanwa.

Ⅹ. Kusanganisa (kaviri cone inotenderera mijama).

Ita shuwa kuti ruvara uye kuita kweiyo yakagadziridzwa mapurasitiki matunhu ataini.

Ⅺ. Kurongedza (zvese-zvemagetsi manhamba ekurapa muchina).

Ⅻ. Chengetedza

Kutumira Nguva: 23-12-22