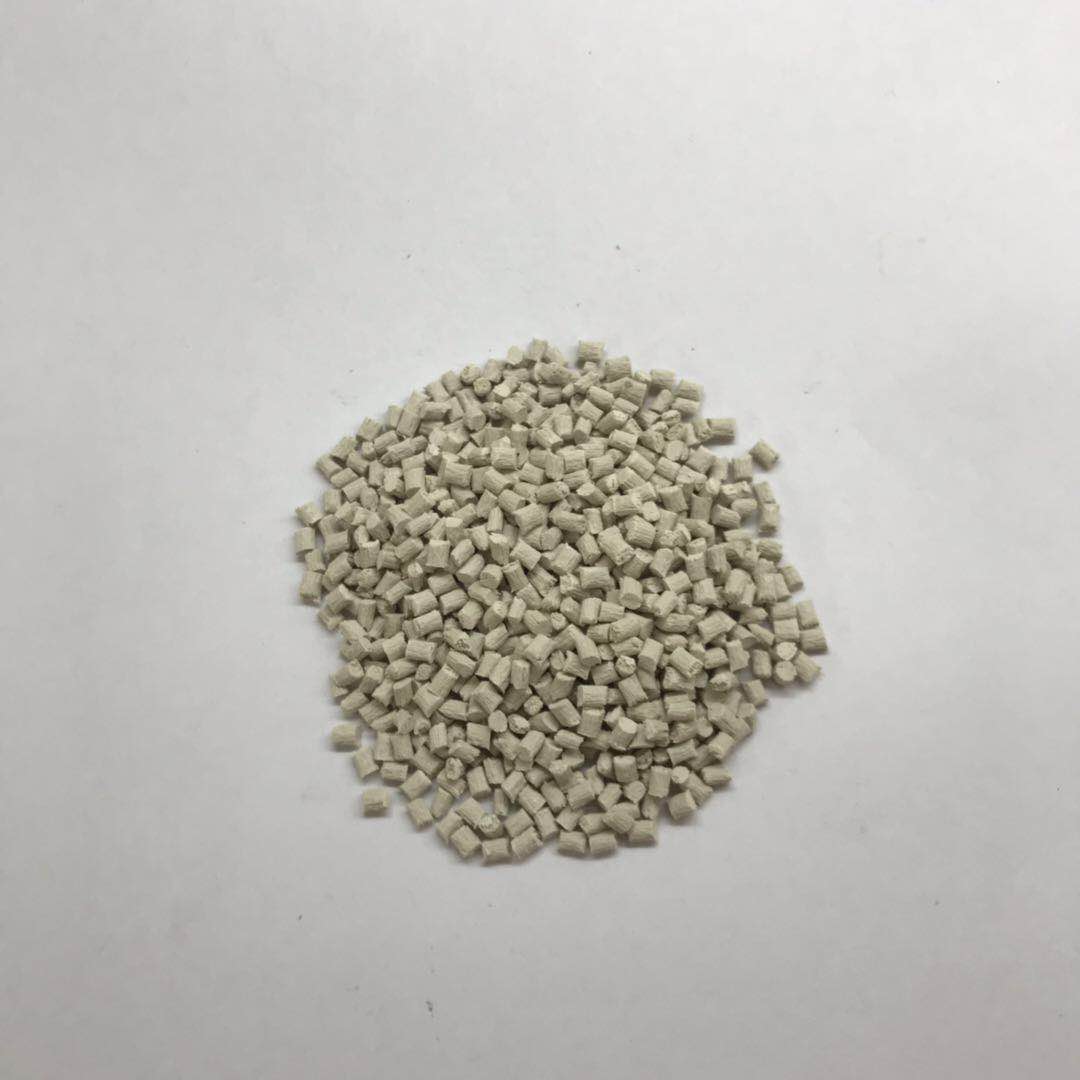

Chii chinonzi Polyphenylene Sulphide (PPS)

PPS inomirira Polyphenylene Sulphide inyanzvi yehuinjiniya thermoplastic inosiyaniswa neatypical musanganiswa wezvivakwa.

Iyo semi-crystalline, opaque uye yakasimba polima ine nzvimbo yakanyanyisa kunyungudika (280 ° C) uye inosanganisira para-phenylene units inochinjana nekubatana kwayo nesarufa.

PPS ine yakanakisa chiyero chezvivakwa senge inherent murazvo kuramba, yakanaka makemikari kuramba, yakakwirira-tembiricha kuramba, dimensional kugona, yakasarudzika mechini simba uye magetsi ekudzivirira.

PPS inogona kugadziriswa nyore nyore nekuti kuoma kwayo kunowedzera nekupisa kwepamusoro.

Ese aya hunhu anotyisa anoita kuti PPS ive yakanakisa imwe nzira kune thermosets nesimbi kuti ishandiswe mune akati wandei maapplication nemidziyo, mota zvikamu uye zvemagetsi.

Vatengi vazhinji muPPS jekiseni rekuumba zvikamu vane mhando yekufunga inertia: hapana tembiricha yekuumbwa, gedhi harina hombe, kupera kwakakwana, nguva pfupi yekutonhora.

Mold tembiricha inogona kuita pamusoro pechigadzirwa nekukurumidza crystallization, yakatsetseka isina inoyangarara faibha kuyerera, chinonyanya kukosha ndechekuita kuti kusimba kwechigadzirwa kusimbiswe zvakanyanya;saizi yegedhi inokanganisa huwandu hwejekiseni repurasitiki, uye pachava nezvinodiwa zvekugadzika kwekumanikidza uye chiyero chejekiseni.Ichavawo nemigumisiro pane distal pressure kurasikirwa kwezvinhu zvakasiyana-siyana.

Kusakwana kupera kunokonzeresa kukurumidza kuunganidzwa kwegasi, zvichikonzera kupisa uye muenzaniso pamusoro uye muswe wechigadzirwa.

PPS pachayo zvinhu zvichange zvine sulfide uye imwe diki diki yepolyphenylbiphenyl polymer precipitation, saka dhizaini yekupedza simba yakakosha!

Nguva pfupi yekutonhora, isingakodzere kune yakazara crystallization yechigadzirwa!

Kuti vateedzere kugona kwekugadzira, vatengi vazhinji vanodzikisa zvakananga kutenderera kwekugadzira kusvika pamwero mukuru, zvichikonzera kupfupika kwezvinhu crystallization kutenderera, izvo zvisingaenderane nemhinduro yechiitiko mune yekutanga!

Kusarudzwa kunonzwisisika kwezvinhu, kugadzira kwesainzi!

Ipa imwe-yekumira rutsigiro kubva kune mbishi zvinhu, mold, maitiro, zvakapedzwa zvigadzirwa, zvichemo zvevatengi uye imwe izere cheni!

Yepamusoro pekuita zvinhu zvakakukomberedza iwe imwe-stop mhinduro nyanzvi!

Nguva yekutumira: 29-10-21