Biodegradable firimu yakagadziridzwa zvinyorwa-spla

Iko kushandiswa kwePolylactic acid ikozvino inowedzera mushonga kune zvakajairika zvinhu zvakadai semabhegi ekuisa, mafirimu ezvirimwa, machira emakapu uye makapu uye makapu. Kurongedza zvinhu zvinogadzirwa kubva paridhi acid pakutanga kwaitanga kudhura, asi ikozvino wave chimwe chezvinhu zvinowanzoitika zvekutakura zvinhu. Poly (lactic acid) inogona kugadzirwa mumachira nemafirimu nekukweva, jekiseni kuumbwa uye kutambanudza. Mvura uye Mhepo Preemily yePolylactic acid firimu iri yakaderera pane iyo yePolystyrene firimu. Sezvo mvura uye gasi mamorekuru vevana veAmorphous of the polymer, mvura uye mhepo yekufungidzira yePolylactic acid firimu inogona kugadziridzwa nekugadzirisa crystalline yePolylactic acid.

Tekinoroji yakati wandei yakadai sekuwedzera, kuwedzera vamiriri venyama, vachigadzira makomposhi nemafaira kana nano-tarisiro uye kuunza zvivakwa zvekuchinjisa zvave zvichisimudzira manhamba ePlong. Polylactic acid inogona kuongororwa senge yakawanda thermoplastics mu fiber (semuenzaniso, ichishandisa nguva yekunyungudika yekuputika) uye firimu. Pla ane zvakafanana mechantices kune pete pete polymer, asi ine zvakanyanya kuderera kwakanyanya kuenderera mberi kushandisa tembiricha. Ine simba repamusoro simba, pla ine nyore kudhindwa uko kunoita kuti iwaniswe zvakanyanya mu3-D kudhinda. Simba reChinese re3-D rakadhindwa Pl rakambofunga.

Spla maficha

Tsananguro yeBioderadable Purasitiki, sekusikwa, senge ivhu, jecha, nharaunda yemvura yakakonzerwa nekugadzira microbial chiitiko chekuvapo kwechisikigo, MuCarbon Dioxide (CO2) uye / kana methane (Ch4), mvura (H2O) uye iyo Biomass itsva (semuviri wehutachiona (etc.) wepurasitiki.

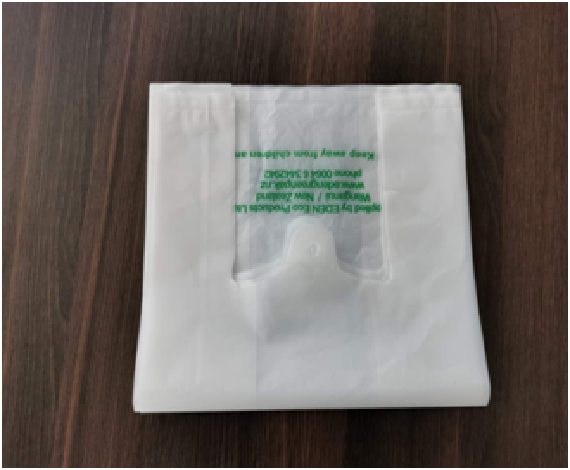

Spla Main application shamba

Izvo zvinogona kutsiva zvachose zvetsika mapurasitiki mapepa ekutengesa, senge mabhegi ekutenga, mabhegi, anotaridza mabhegi, mabhegi emarara, mabhegi emarara, ethsstring mabhegi, nezvimwe.

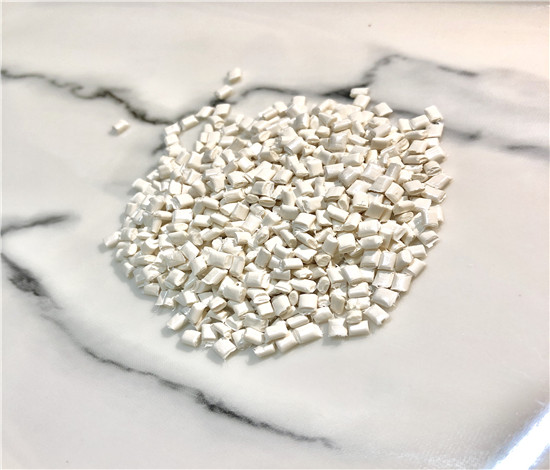

Spla mamakisi uye tsananguro

| Giredhi | Tsananguro | Kugadzirisa Mirayiridzo |

| SPLA-F111 | Izvo zvinhu zvikuru zve spla-f11 zvigadzirwa zviri pla uye pbat, uye zvigadzirwa zvavo zvinogona kuve 100% biodegarded mushure mekushandisa kabhoni uye mvura, pasina kusvibisa nharaunda. | Paunenge uchishandisa SPLA-F111 Blown Firimu pane inokudzwa firimu yekugadzira firimu mutsara, iyo yakakurudzirwa yekurova firimu yekugadzirisa tembiricha ndeye 140-160 ℃. |

| SPLA-F112 | Izvo zvinhu zvikuru zve spla-f11 zvigadzirwa zviri pla, pbat uye zvigadzirwa zvaro zvinogona kuve 100% biodegarded mushure mekushandiswa uye kurasa carbon dioxide uye mvura isina kusvibisa nharaunda. | Paunenge uchishandisa SPLA-F112 Blown Firimu muBlown Film Production Line, iyo Yakakurudzirwa Kuputika Firimu yekugadzirisa tembiricha ndeye 140-160 ℃. |

| SPLA-F113 | Izvo zvinhu zvikuru zve spla-f11 zvigadzirwa zviri pla, pbat uye zvinhu zvisikwa. Zvigadzirwa izvo zvinogona kuve 100% biodegazed mushure mekushandiswa uye kuraswa, uye pakupedzisira kuburitsa kabhoni dioxide uye mvura isina kusvibisa nharaunda. | Paunenge uchishandisa SPLA-F113 FICE MUFANANIDZO muBlown Firimu Production Line, iyo Yakakurudzirwa Kuputika Firimu yekugadzirisa tembiricha ndeye 140-165 ℃. |

| SPLA-F114 | Iyo SPLA-F11T chigadzirwa ndeye starch-yakazadzwa polyethyle yakagadziridzwa masterbatch. Inoshandisa 50% yemiriwo-yakatorwa starch panzvimbo yePolyethylene kubva kuPetrochemical zviwanikwa. | Iyo chigadzirwa chakasanganiswa nePolyethylene pane yakaburitswa firimu yekugadzira mutsara. Iyo yakakurudzirwa yekuwedzera mari ndeye 20-60WT%, uye iyo inovharira firimu yekugadzirisa tembiricha ndeye 135-160 ℃. |